Pull-In-Place Pipelining: A Comprehensive Guide to Installation Methods and Procedures

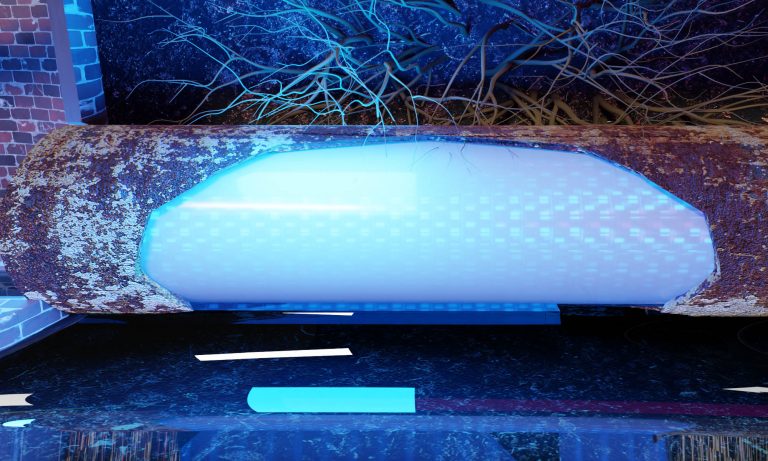

Pull-in-place pipelining is a highly effective and widely adopted method for rehabilitating deteriorated or damaged pipelines without the need for extensive excavation and replacement. It is a trenchless technology that offers significant cost savings, minimizes disruption to the surrounding environment, and ensures a rapid and efficient restoration of pipeline functionality. Different manufacturers may have varying specific installation procedures, but the fundamental principles and steps involved in pull-in-place pipelining remain consistent across the industry. In this article, we will delve into the intricacies of pull-in-place pipelining methods, exploring the techniques, equipment, and considerations involved in this innovative pipeline rehabilitation process. Pull-in-place pipelining, also known as cured-in-place pipe (CIPP) lining, involves installing a new pipe within the existing damaged pipeline by using a flexible liner impregnated with a resinous material. The liner is inserted into the pipeline and then inflated or pulled into place, conforming to the shape of the existing pipe. Once in position, the resin is cured, creating a structurally sound and corrosion-resistant pipe within the original infrastructure. The full process of pull-in-place pipelining The process of pull-in-place pipelining can be divided into several key stages, including preparation, cleaning, liner installation, curing, and final inspection. While the overall procedure is