Introduction:

Cast iron sewer pipes have long been a popular choice for residential and commercial plumbing systems due to their durability and strength. However, over time, these pipes can deteriorate and develop various issues, such as cracks, leaks, and corrosion. Repairing or replacing cast iron sewer pipes has traditionally involved invasive and expensive excavation methods. However, with the advent of trenchless pipelining, homeowners and plumbers now have a cost-effective and minimally disruptive solution at their disposal. In this article, we will explore the benefits of trenchless pipelining and delve into the step-by-step process of fixing cast iron sewer pipes.

Understanding Cast Iron Sewer Pipe Problems:

Before we delve into the solution, it is crucial to understand the common problems that afflict cast iron sewer pipes. Over the years, these pipes can suffer from corrosion, tree root intrusion, cracking, and misaligned joints. These issues can result in blockages, reduced water flow, foul odors, and even structural damage to the property. If left unaddressed, these problems can escalate, leading to costly repairs and potential health hazards.

Introducing Trenchless Pipelining:

Trenchless pipelining, also known as cured-in-place pipe (CIPP) lining, is a revolutionary technique that offers a non-invasive and efficient solution for rehabilitating cast iron sewer pipes. Unlike traditional methods that require extensive excavation and replacement, trenchless pipelining involves creating a new pipe within the existing damaged one. This approach not only saves time but also significantly reduces costs and disruption to the property.

The Trenchless Pipelining Process:

- Inspection and Assessment: The first step in fixing cast iron sewer pipes using trenchless pipelining is to conduct a thorough inspection. This typically involves using advanced camera technology to assess the condition of the pipes, identify the extent of the damage, and locate any blockages or obstructions. A professional plumber will use this information to determine the most suitable approach for the repair.

- Pipe Cleaning and Preparation: Before the pipelining process begins, the cast iron sewer pipes must be thoroughly cleaned to remove any debris, scale, or obstructions. High-pressure water jetting or mechanical cleaning methods can be employed to ensure the pipe’s interior is free from any impediments that could affect the new lining’s adhesion.

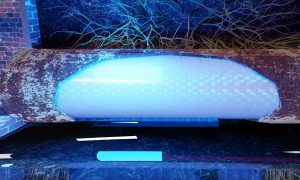

- Lining Installation: Once the pipe is clean and prepared, the trenchless pipelining process can commence. A flexible resin-saturated liner, often made of felt or fiberglass, is inserted into the damaged cast iron sewer pipe. The liner is inflated and pressed against the interior walls of the pipe, conforming to its shape.

- Curing the Liner: To create a new, structurally sound pipe within the old one, the resin-saturated liner must be cured. This is typically achieved by introducing hot water or steam into the liner, causing it to harden and adhere to the inner walls of the existing pipe. The curing process may take several hours, allowing the resin to fully solidify and form a seamless and durable lining.

- Final Inspection and Testing: Once the curing process is complete, a final inspection is conducted to ensure the newly installed pipe is free from defects and meets the required standards. Using the camera technology mentioned earlier, the plumber will examine the integrity of the liner and check for any imperfections or irregularities. Additionally, a hydrostatic pressure test may be performed to verify the strength and watertightness of the rehabilitated pipe.

Benefits of Trenchless Pipelining:

Trenchless pipelining offers numerous advantages over traditional methods of fixing cast iron sewer pipes. Let’s explore some of these benefits:

- Cost-Effectiveness: Trenchless pipelining eliminates the need for extensive excavation, saving homeowners significant costs associated with property restoration, such as landscaping and hardscaping repairs. Additionally, the reduced labor and equipment requirements contribute to overall cost savings.

- Minimal Disruption: Unlike traditional pipe replacement methods, trenchless pipelining minimizes disruption to the property. There is no need to excavate large trenches, minimizing damage to landscaping, driveways, and other structures. The repair process is efficient and can often be completed within a day, allowing homeowners to resume their daily activities quickly.

- Enhanced Pipe Longevity: Trenchless pipelining provides a long-lasting solution to cast iron sewer pipe problems. The new liner, made of durable materials, resists corrosion, root intrusion, and other common issues. As a result, homeowners can enjoy an extended lifespan for their sewer system, reducing the need for frequent repairs or replacements.

- Environmentally Friendly: The trenchless pipelining process reduces the carbon footprint associated with traditional pipe replacement. With minimal excavation and reduced transportation of materials, the impact on the environment is significantly reduced. Additionally, the longevity of the rehabilitated pipe reduces future waste generated from replacement projects.

Conclusion:

The advent of trenchless pipelining has revolutionized the way we repair and rehabilitate cast iron sewer pipes. This cost-effective and minimally disruptive technique offers homeowners and plumbers a practical solution for addressing pipe deterioration, cracks, and leaks. By understanding the process involved in trenchless pipelining and recognizing its numerous benefits, homeowners can make informed decisions about the repair and maintenance of their sewer systems. Embracing this innovative approach ensures the longevity and efficiency of cast iron sewer pipes, providing peace of mind and preserving the integrity of our plumbing infrastructure for years to come.