Maintaining the functionality and longevity of sewer systems is crucial for the smooth functioning of any city’s infrastructure. Cured-in-place pipelining (CIPP) has emerged as a highly effective and cost-efficient method for rehabilitating damaged sewer lines. This innovative trenchless technology involves the installation of a seamless pipe within an existing damaged pipe, eliminating the need for extensive excavation. In this article, we will explore the various methods used to install CIPP, highlighting their benefits and applications.

Continuous Inversion Method:

The inversion method is one of the most common techniques used to install CIPP liners. It involves saturating a flexible fabric tube or liner with a liquid resin, which is then inverted or turned inside out through the damaged pipe using either water or air pressure. As the liner unfolds and adheres to the host pipe, the resin is cured, forming a solid, durable pipe within the existing infrastructure. This method is particularly useful for straight pipe sections, and it can navigate bends and curves with proper planning.

Pull-In-Place Method:

The pull-in-place method involves the installation of a resin-impregnated liner through an access point using a winch or cable system. The liner is carefully pulled into position, conforming to the shape of the existing pipe. Once properly positioned, the liner is cured using hot water, steam, or ultraviolet light. This technique is advantageous for rehabilitating pipes with multiple bends, irregular shapes, or tight access points. It allows for precise installation and minimizes the risk of liner wrinkling or folding.

Inversion with Guided Air/Water Method:

To address challenging pipe conditions such as vertical stacks or large-diameter pipes, the inversion method can be combined with guided air or water. A specialized inversion device, equipped with a guide or hose, is inserted into the damaged pipe. As the inversion progresses, the guide ensures that the liner follows the desired path, preventing liner buckling or misalignment. This method provides enhanced control over liner placement and is commonly used in complex sewer systems.

Spray Lining Method:

The spray lining method involves spraying a liquid resin directly onto the inner surface of the damaged pipe using a robotic spray head. The resin is evenly distributed, creating a uniform liner that adheres to the pipe walls. The sprayed resin is then cured using heat or ultraviolet light, resulting in a strong, seamless pipe. This method is highly versatile and can be used for pipes with irregular shapes, transitions, and changes in diameter. It is also effective for repairing joints and localized defects.

Sectional Point Repair Method:

In instances where only a small section of the sewer line requires rehabilitation, the sectional point repair method is a viable option. This approach involves installing a pre-made CIPP liner or a custom-fabricated liner at the specific damaged section. The liner is typically inserted into the host pipe using a winch or inversion method. Once in place, the liner is cured and creates a seamless, durable repair. This method is cost-effective and minimizes disruption to the overall sewer system.

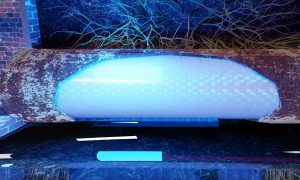

Ultraviolet Cure Method or UV Cure

The UV cure method involves the use of ultraviolet light to cure the resin-impregnated liner. Once the liner is positioned within the damaged pipe, UV light is introduced through the liner wall. The UV light triggers a photochemical reaction that rapidly cures the resin, creating a solid and durable pipe. This method offers several advantages, including faster curing times and reduced reliance on hot water or steam. It is particularly suitable for smaller-diameter pipes or situations where heat curing may be challenging or impractical.

As cities continue to face aging sewer systems, the versatility and benefits of CIPP, including the UV cure method, make it a valuable tool in maintaining the functionality and longevity of vital underground infrastructure. With its ability to rehabilitate pipes with minimal disruption and cost, CIPP has become an indispensable asset in the ongoing effort to ensure efficient and reliable sewer systems. By implementing these innovative installation methods, municipalities and utility companies can address pipe deterioration, extend the lifespan of existing infrastructure, and reduce the need for costly and time-consuming traditional excavation methods.

Revolutionary Changes to Sewer Repair

Cured-in-place pipelining has revolutionized sewer line rehabilitation, offering a range of installation methods tailored to specific pipe conditions and requirements. Whether it is the inversion, pull-in-place, inversion with guided air/water, spray lining, sectional point repair, or UV cure method, CIPP provides an efficient, cost-effective, and environmentally friendly solution. These installation methods significantly reduce the need for extensive excavation and minimize disruption to surrounding infrastructure.