Trenchless technology has transformed the field of pipeline rehabilitation, offering efficient and cost-effective methods for repairing aging and damaged pipelines without the need for extensive excavation. Among the various trenchless techniques, cured in-place pipelining (CIPP) has gained significant popularity due to its ability to create a seamless, jointless pipe within the existing host pipe. In recent years, ultraviolet (UV) cured in-place pipelining methods have emerged as a superior alternative to the traditional steam-cure methods. This article aims to explore the numerous advantages of UV cured in-place pipelining over older steam-cure methods and shed light on the revolutionary impact it has on the pipeline rehabilitation industry.

Understanding the Cured In-Place Pipelining Process

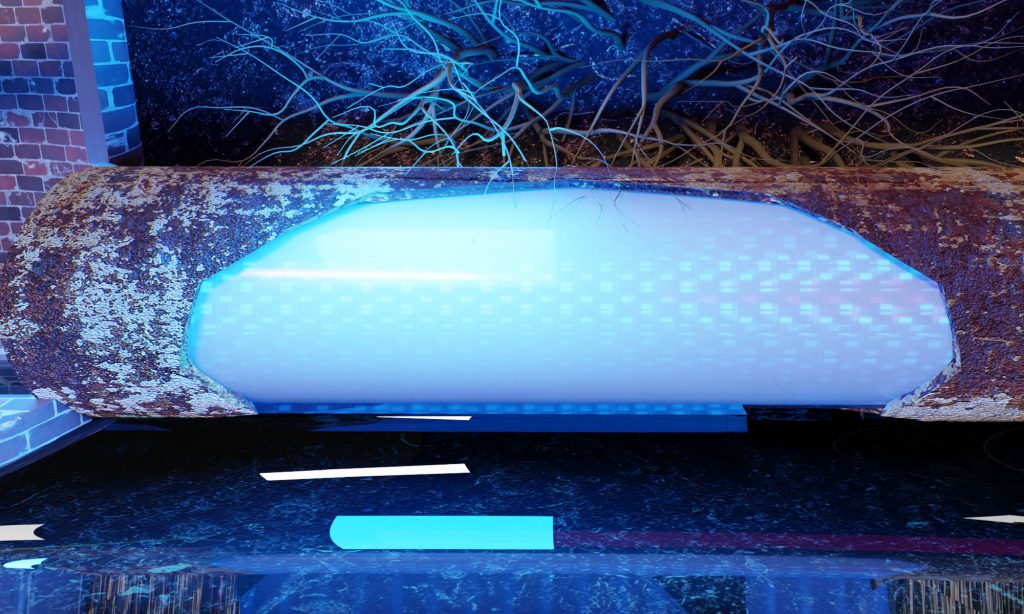

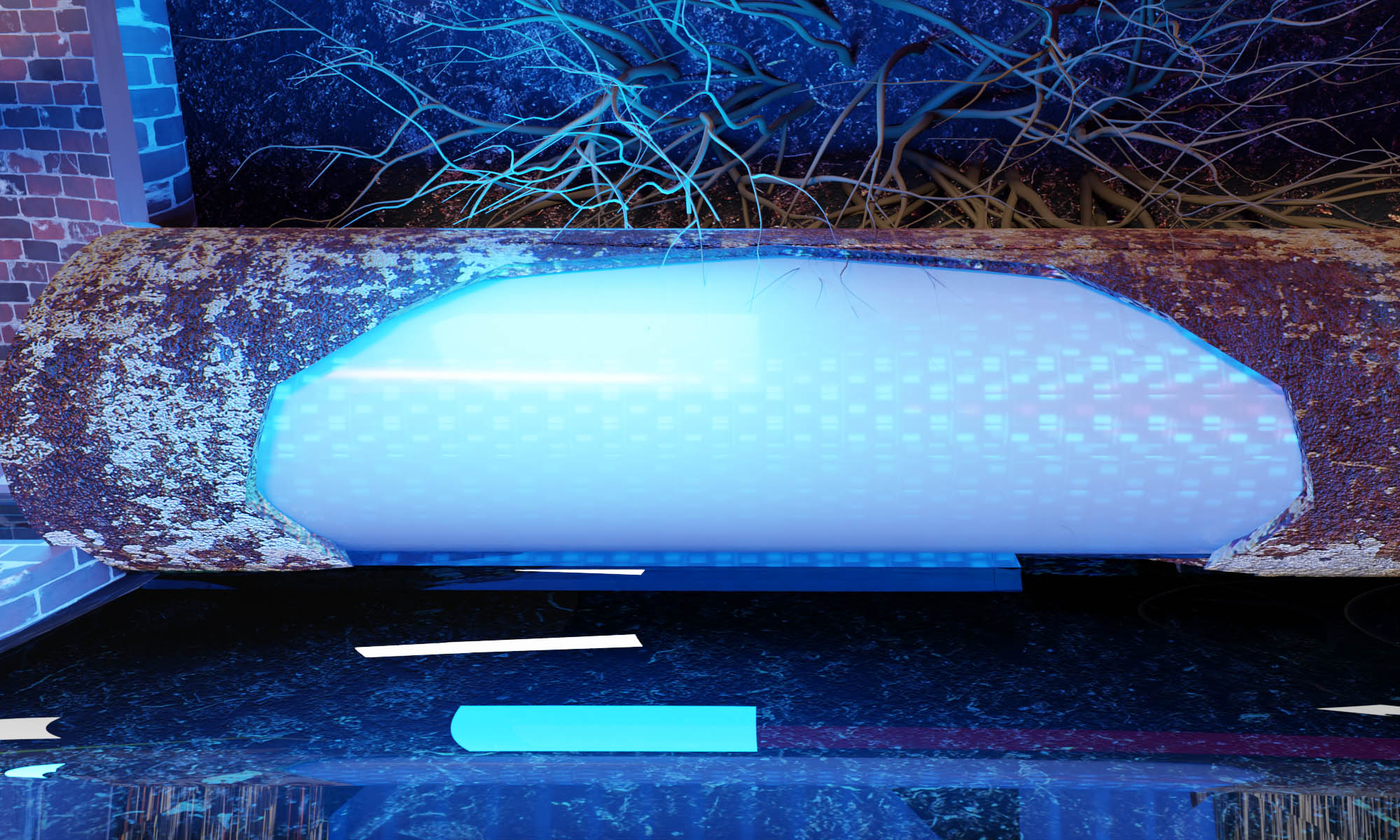

Before delving into the specific differences between UV cured and steam-cure methods, it is essential to comprehend the basics of the CIPP process. CIPP involves installing a liner, typically made of polyester or fiberglass, into the existing pipeline. The liner is saturated with a thermosetting resin that, upon curing, forms a robust and durable pipe within the host pipe.

Traditionally, steam-cure methods have been employed to cure the resin and create the new pipe. This process involves introducing steam into the liner, which heats and activates the resin, causing it to cure and harden. However, the advent of UV cured in-place pipelining has revolutionized this process by introducing an alternative curing mechanism that offers numerous advantages.

Advantages of UV Cured In-Place Pipelining

- Rapid Cure Time: One of the most significant advantages of UV cured in-place pipelining is its remarkably fast cure time. Unlike steam-cure methods, which can take several hours or even days to complete the curing process, UV curing occurs almost instantly. By utilizing UV light, the resin is cured within minutes, significantly reducing the time required to complete a rehabilitation project. This efficiency allows for quicker project turnaround, minimizing disruptions to the surrounding infrastructure and communities.

- Precise Control of Cure Depth: UV cured in-place pipelining offers precise control over the depth of cure. With steam-cure methods, the heat applied to the liner can sometimes lead to an inconsistent curing depth, resulting in weaker sections of the pipe. In contrast, UV curing ensures a uniform and consistent cure depth throughout the entire pipeline, enhancing the structural integrity and longevity of the rehabilitated pipe.

- Enhanced Safety and Environmental Benefits: The use of UV light for curing eliminates the need for steam, significantly reducing the risks associated with high-pressure steam generation and handling. Steam-cure methods require specialized equipment and extensive safety precautions, which can pose hazards to workers and the environment. UV cured in-place pipelining minimizes these risks, making it a safer and more environmentally friendly alternative.

- Improved Quality Control: UV cured in-place pipelining offers improved quality control during the curing process. UV light allows real-time monitoring and inspection of the curing process, ensuring that each section of the pipe is adequately cured. Steam-cure methods, on the other hand, rely on indirect monitoring techniques and post-cure inspections, which may not provide immediate feedback on the quality of the installation.

- Flexibility in Application: UV cured in-place pipelining provides greater flexibility in its application. The use of UV light allows the curing process to occur in a wide range of ambient temperatures, making it suitable for various climatic conditions. Additionally, UV curing can be used for both small-diameter and large-diameter pipes, expanding its applicability to a broader range of pipeline sizes and types.

- Cost-Effectiveness: While the upfront cost of UV cured in-place pipelining equipment may be higher compared to steam-cure methods, the overall cost-effectiveness of UV curing becomes apparent when considering project timelines and labor costs. The rapid cure time of UV curing translates into shorter project durations, reducing labor expenses and minimizing the potential for revenue loss due to extended downtime. Furthermore, the enhanced quality control and durability of UV cured pipes result in reduced maintenance and repair costs over the lifespan of the rehabilitated pipeline.

UV cured in-place pipelining has revolutionized the field of trenchless pipeline rehabilitation, offering a range of advantages over older steam-cure methods. With its rapid cure time, precise control of cure depth, enhanced safety, improved quality control, flexibility in application, and cost-effectiveness, UV cured in-place pipelining has become the preferred choice for many pipeline rehabilitation projects. As technology continues to advance, it is expected that UV cured in-place pipelining methods will further evolve, providing even greater efficiencies and benefits to the industry. The future of trenchless technology lies in the continued innovation and adoption of UV cured in-place pipelining, enabling the sustainable and efficient repair of our aging underground infrastructure.