Continuous Inversion Pipelining Methods: A Comprehensive Guide

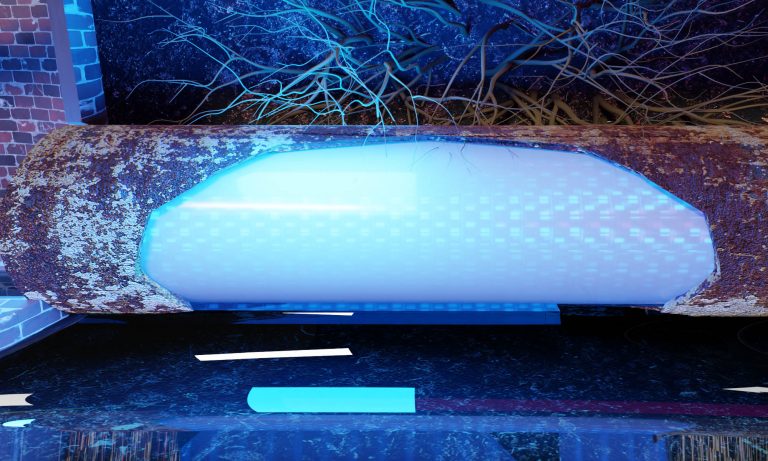

In the realm of pipeline construction, continuous inversion pipelining methods have emerged as a revolutionary technique. This approach has gained traction due to its efficiency and cost-effectiveness in installing underground pipelines. By utilizing the principles of inversion and gravity, continuous inversion pipelining enables the seamless installation of various types of pipelines, including sewer lines, water mains, and gas conduits. While different manufacturers may have specific installation procedures, this article aims to provide a comprehensive overview of how continuous inversion pipelining methods are typically performed. Understanding Continuous Inversion Pipelining Continuous inversion pipelining involves a process wherein a flexible liner, typically made of high-density polyethylene (HDPE) or polyvinyl chloride (PVC), is inverted into an existing pipe. The inversion process relies on the controlled flow of a liquid medium, such as water or air, to turn the liner inside out. This method ensures that the liner conforms to the shape and size of the host pipe, effectively creating a new pipe within the old one. The process of continuous inversion pipelining offers several advantages over traditional open-cut or trenchless methods. Firstly, it minimizes disruption to the surrounding environment, as excavation is significantly reduced. This aspect is particularly valuable in urban areas, where minimizing