When it comes to the world of infrastructure and utilities, few things are as vital as pipelines. These intricate networks ensure the efficient transportation of water, sewage, and other essential materials. However, as time goes by, these pipelines deteriorate, posing significant challenges for the communities they serve. In the past, repairing or replacing pipelines involved disruptive and costly excavation methods. Fortunately, a groundbreaking innovation has emerged – trenchless pipelining. This revolutionary technique offers a transformative solution, especially when it comes to fixing High-Density Polyethylene (HDPE) pipes. In this article, we will delve into the world of trenchless sewer repair and explore how it can rejuvenate HDPE pipes, bringing numerous benefits to the table.

To fully appreciate the significance of trenchless pipelining, it is crucial to understand the unique properties and challenges associated with HDPE pipes. High-Density Polyethylene pipes are renowned for their durability, flexibility, and resistance to corrosion. These pipes are widely used in various industries and infrastructure projects due to their exceptional strength and longevity. However, even the most resilient materials are not immune to the effects of time, environmental factors, and wear and tear.

Traditional pipe repair methods, such as open-cut excavation, can cause extensive disruption to the surrounding areas. Moreover, excavating and replacing HDPE pipes can be an expensive and time-consuming endeavor. This is where trenchless sewer repair shines, offering a non-invasive and cost-effective alternative that extends the lifespan of HDPE pipes without the need for disruptive digging.

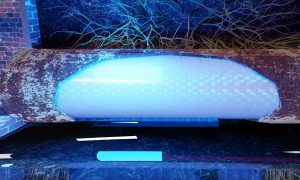

Trenchless pipelining, also known as cured-in-place pipe (CIPP) lining, has revolutionized the world of pipe rehabilitation. This innovative technique involves rehabilitating existing pipes by inserting a resin-saturated liner into the damaged pipe section. Once in place, the liner is cured using heat or UV light, creating a strong, seamless, and durable pipe-within-a-pipe. This process eliminates the need for excavation and allows for the rehabilitation of HDPE pipes without disrupting the surrounding environment.

The benefits of trenchless pipelining for HDPE pipes are nothing short of remarkable. Firstly, this technique significantly reduces project timelines, minimizing the downtime of critical infrastructure. Traditional methods often require weeks or even months to complete, causing significant disruption to businesses, communities, and the environment. In contrast, trenchless sewer repair can be completed in a fraction of the time, enabling a swift return to normal operations.

Furthermore, trenchless pipelining is a cost-effective solution for HDPE pipe repair. Traditional excavation methods involve substantial costs associated with labor, heavy machinery, material disposal, and site restoration. With trenchless technology, these expenses are significantly reduced since there is no need for extensive digging and restoration. This makes trenchless pipelining an economically viable choice, especially for municipalities, utility companies, and private businesses looking to optimize their budgetary allocations.

The non-invasive nature of trenchless sewer repair also ensures minimal disruption to daily activities and the surrounding environment. Traditional excavation methods often necessitate the removal of trees, pavement, and even structures. This can lead to traffic congestion, environmental damage, and a host of inconveniences for nearby residents and businesses. Trenchless pipelining eliminates these issues, preserving the integrity of the surroundings and maintaining a harmonious balance between infrastructure and nature.

Moreover, HDPE pipes repaired using trenchless methods experience a significant increase in their structural integrity. The cured-in-place liner forms a seamless and jointless pipe, minimizing the risk of leaks, cracks, and intrusion from external elements. The liner’s resin material provides additional protection against corrosion, extending the overall lifespan of the HDPE pipe system. By reinforcing the existing infrastructure, trenchless pipelining ensures a reliable and long-lasting solution that stands the test of time.

In addition to its cost-effectiveness, speed, and durability, trenchless pipelining also offers a flexible approach to HDPE pipe repair. The technique can be used to rehabilitate pipes of various diameters, shapes, and lengths, making it a versatile solution for a wide range of projects. Whether it’s a small section of pipe or an extensive network, trenchless sewer repair can be customized to suit the specific needs and challenges of each situation. This adaptability further emphasizes the effectiveness and practicality of trenchless technology for HDPE pipes.

Another key advantage of trenchless pipelining is its ability to minimize environmental impact. With growing concerns about sustainability and carbon footprint reduction, the preservation of ecosystems and natural resources is paramount. By eliminating the need for large-scale excavation, trenchless sewer repair reduces soil displacement, air pollution, and habitat disruption. This eco-friendly approach aligns with the principles of sustainable development and responsible infrastructure management, contributing to a greener and more environmentally conscious future.

In conclusion, trenchless pipelining represents a game-changing innovation in the field of pipe rehabilitation, particularly for HDPE pipes. This revolutionary technique offers a multitude of benefits, including reduced project timelines, cost-effectiveness, minimal disruption, enhanced structural integrity, and environmental sustainability. By embracing trenchless sewer repair, communities, utility companies, and businesses can effectively rejuvenate their HDPE pipe systems without the need for disruptive and expensive excavation. With its transformative potential and wide-ranging advantages, trenchless pipelining is undoubtedly the future of HDPE pipe repair.