In the realm of plumbing, a broken or damaged pipe can quickly become a homeowner’s worst nightmare. Traditional repair methods, such as digging trenches to access the faulty pipes, can be costly, time-consuming, and disruptive. Fortunately, the plumbing industry has witnessed a remarkable innovation in recent years – trenchless pipelining or trenchless sewer repair. This groundbreaking technique has transformed the way we address issues with PVC (Polyvinyl Chloride) pipes, offering homeowners a more efficient, cost-effective, and hassle-free solution. Let’s dive into the world of trenchless pipelining and explore how it can revolutionize PVC pipe repair.

PVC pipes have become a staple in residential and commercial plumbing systems due to their durability, versatility, and affordability. However, like any other material, PVC pipes are not impervious to wear and tear. Over time, they can develop cracks, leaks, or even collapse, compromising the entire plumbing infrastructure. Traditionally, addressing these issues involved extensive excavation and pipe replacement, leading to significant disruption, property damage, and exorbitant costs.

Enter trenchless pipelining – a technique that eliminates the need for disruptive digging, providing a far less invasive and more efficient approach to repairing PVC pipes. This revolutionary method involves rehabilitating the existing pipes from within, without the need for extensive excavation or pipe replacement. Trenchless pipelining effectively repairs cracks, leaks, and structural damages, restoring the integrity of the PVC pipes and extending their lifespan.

One of the key advantages of trenchless pipelining is its non-destructive nature. Instead of tearing up lawns, driveways, or flooring, technicians can access the damaged PVC pipes through existing access points, such as cleanouts or manholes. This eliminates the need for extensive excavation, drastically reducing disruption to the property and minimizing the associated costs. Homeowners can avoid the headache of dealing with post-repair landscaping or renovation, saving both time and money.

The trenchless pipelining process begins with a thorough inspection of the PVC pipes using state-of-the-art technology, such as closed-circuit television (CCTV) cameras. This inspection allows technicians to identify the exact location and extent of the damage, providing valuable information for developing a tailored repair plan. Once the assessment is complete, the pipe is cleaned using high-pressure water jetting or mechanical means to remove debris, scale, and obstructions, ensuring a smooth surface for the lining.

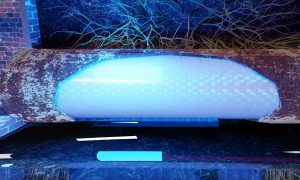

After cleaning, the real magic happens – the trenchless pipelining crew inserts a flexible and durable liner into the damaged PVC pipe. This liner, usually made of resin-impregnated felt or fiberglass, is carefully measured and cut to fit the specific dimensions of the pipe. Using specialized equipment, the liner is inserted into the pipe and inflated, adhering to the walls and effectively creating a new pipe within the old one.

The resin-impregnated liner is then cured in place, either through the use of hot water or ultraviolet light, depending on the specific materials and installation method. As the liner cures, it hardens and bonds with the existing PVC pipe, creating a seamless, corrosion-resistant, and structurally sound conduit. This rehabilitated pipe boasts enhanced durability, improved flow capacity, and resistance to future damages, making it a long-term and cost-effective solution for PVC pipe repair.

The benefits of trenchless pipelining extend far beyond the seamless repair process. This innovative technique also offers significant environmental advantages. By minimizing excavation and preserving existing infrastructure, trenchless pipelining reduces the carbon footprint associated with traditional pipe repair methods. It conserves natural resources, minimizes waste generation, and helps maintain the ecological balance of the surrounding area. Homeowners can contribute to sustainability efforts while resolving their PVC pipe issues – a win-win situation for both their wallets and the environment.

Moreover, trenchless pipelining provides a quicker turnaround time compared to traditional pipe repair methods. While traditional repairs can take several days or even weeks to complete, trenchless pipelining typically requires a fraction of the time. Homeowners can enjoy the comfort of restored plumbing functionality within a matter of hours or a few days, depending on the complexity of the project. The speedy repair process minimizes inconvenience, allowing families to resume their daily routines without prolonged disruption.

When it comes to cost-effectiveness, trenchless pipelining shines brightly. Although the initial investment may seem higher than traditional repair methods, considering the advanced technology and specialized materials involved, the long-term benefits outweigh the costs. Trenchless pipelining eliminates the need for extensive excavation, pipe replacement, and subsequent property restoration expenses. It also prevents potential damage to underground utilities, further reducing repair costs. Ultimately, homeowners save money by opting for trenchless pipelining, enjoying the peace of mind that comes with a reliable, long-lasting PVC pipe repair.

In conclusion, trenchless pipelining has emerged as a game-changer in the world of PVC pipe repair. Its non-destructive nature, efficient repair process, environmental friendliness, and cost-effectiveness make it an appealing choice for homeowners facing PVC pipe issues. By bypassing the need for disruptive excavation, trenchless pipelining minimizes inconvenience, preserves landscaping, and saves both time and money. With its ability to rehabilitate PVC pipes seamlessly, this innovative technique ensures the longevity and functionality of plumbing systems, bringing smiles to homeowners’ faces. Embrace the power of trenchless pipelining and bid farewell to the days of traditional, cumbersome PVC pipe repairs.