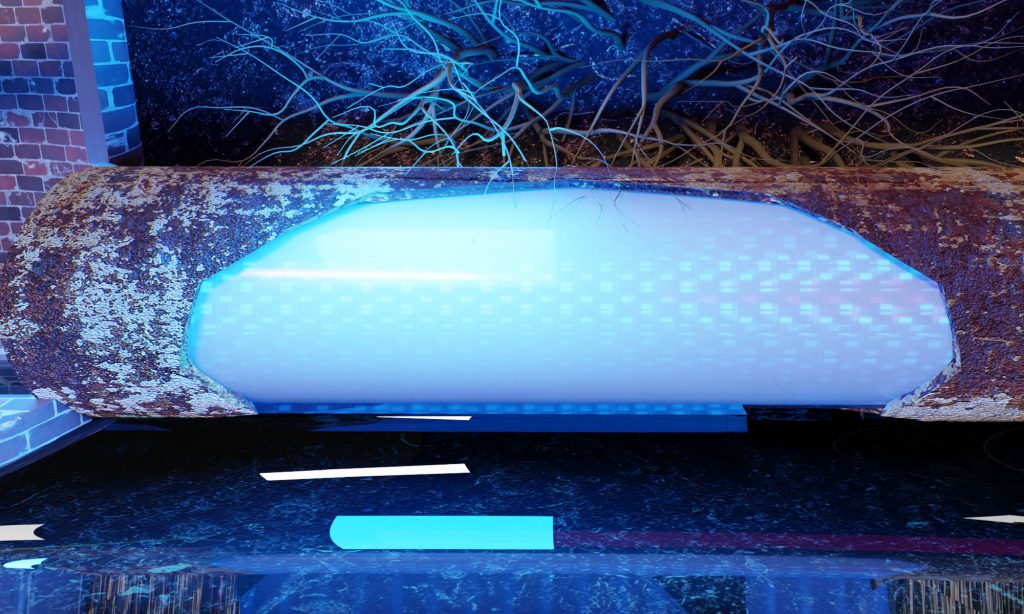

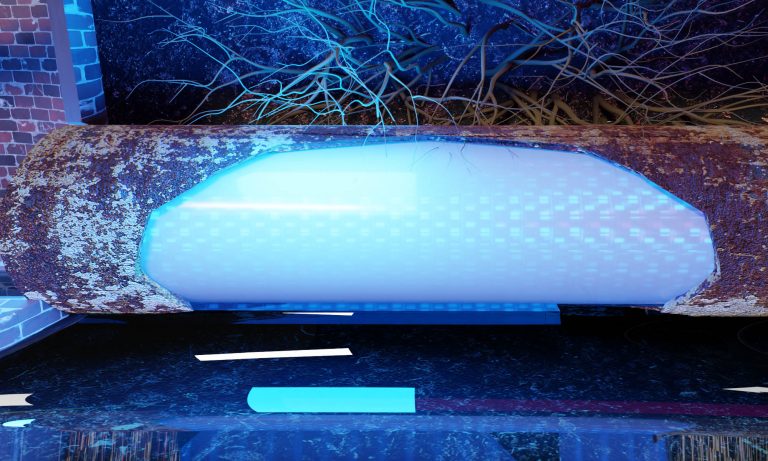

Ultraviolet Cured In-Place Pipelining: A Revolution in Trenchless Technology

Trenchless technology has transformed the field of pipeline rehabilitation, offering efficient and cost-effective methods for repairing aging and damaged pipelines without the need for extensive excavation. Among the various trenchless techniques, cured in-place pipelining (CIPP) has gained significant popularity due to its ability to create a seamless, jointless pipe within the existing host pipe. In recent years, ultraviolet (UV) cured in-place pipelining methods have emerged as a superior alternative to the traditional steam-cure methods. This article aims to explore the numerous advantages of UV cured in-place pipelining over older steam-cure methods and shed light on the revolutionary impact it has on the pipeline rehabilitation industry. Understanding the Cured In-Place Pipelining Process Before delving into the specific differences between UV cured and steam-cure methods, it is essential to comprehend the basics of the CIPP process. CIPP involves installing a liner, typically made of polyester or fiberglass, into the existing pipeline. The liner is saturated with a thermosetting resin that, upon curing, forms a robust and durable pipe within the host pipe. Traditionally, steam-cure methods have been employed to cure the resin and create the new pipe. This process involves introducing steam into the liner, which heats and activates the resin, causing