Finally, a website dedicated to the information you need to make an educated decision on repairing your sewer line. Consider trenchless technology. Consider trenchless pipelining.

1-800-798-9808

The Pitfalls of Dig & Replace Sewer Repair: Embracing Trenchless Pipelining for Efficient and Cost-Effective Solutions

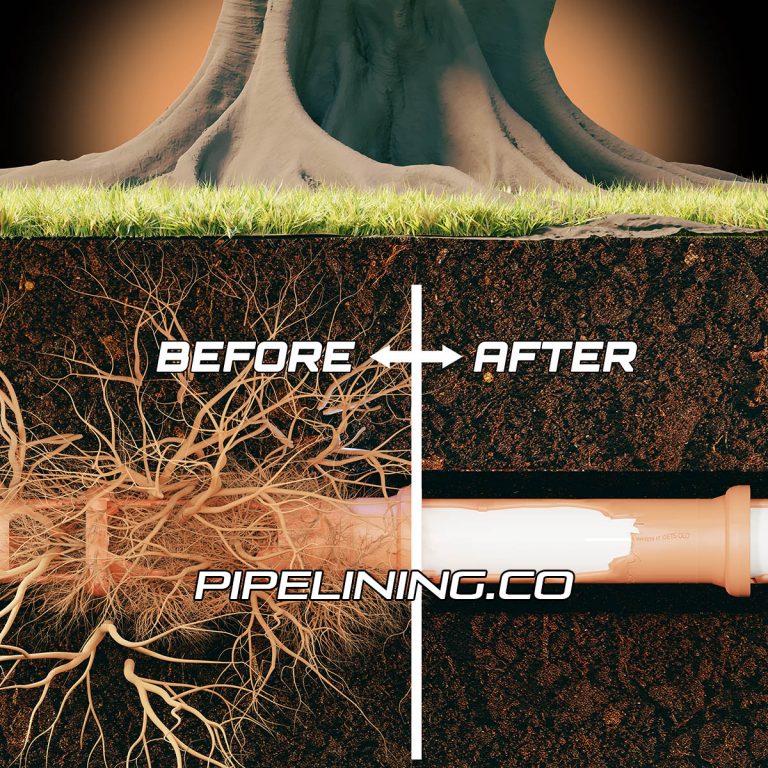

Maintaining the integrity of sewer pipes is crucial to ensure the smooth functioning of our wastewater systems. When sewer pipes develop issues, repairs become necessary to prevent further damage and potential health hazards. Traditionally, dig & replace methods have been employed for sewer repairs. However, advancements in technology have given rise to trenchless pipelining, a more efficient and advantageous alternative.

Trenchless pipelining

The Superior Choice for Efficient and Cost-Effective Pipeline Restoration

When it comes to sewer pipe repair, traditional dig-and-replace methods have long been the go-to solution. However, in recent years, trenchless pipelining has emerged as a revolutionary technique that offers numerous advantages over its conventional counterpart. In this article, we will explore why trenchless sewer repair is a superior choice, focusing on its efficiency, cost-effectiveness, and environmental benefits. If you’re searching for the most innovative solution to address sewer pipe issues, look no further than trenchless sewer repair and use pipelining.co as a good guide on why sewer pipes fail and how they’re repaired.

You may want to start here:

Identifying the 20 Symptoms of a Broken Sewer Line

Here’s the top 9 reasons you should consider trenchless pipe repair

Enhanced Efficiency: Trenchless sewer repair minimizes disruption to property and surrounding infrastructure by eliminating the need for extensive excavation. This non-invasive approach significantly reduces project timelines, allowing for faster completion and minimal inconvenience to homeowners, businesses, and municipalities.

Cost-Effectiveness: By eliminating the need for extensive excavation, trenchless sewer repair reduces labor and equipment costs associated with traditional dig-and-replace methods. This translates to substantial savings for property owners and municipalities, making it an economically viable choice for sewer pipe restoration projects.

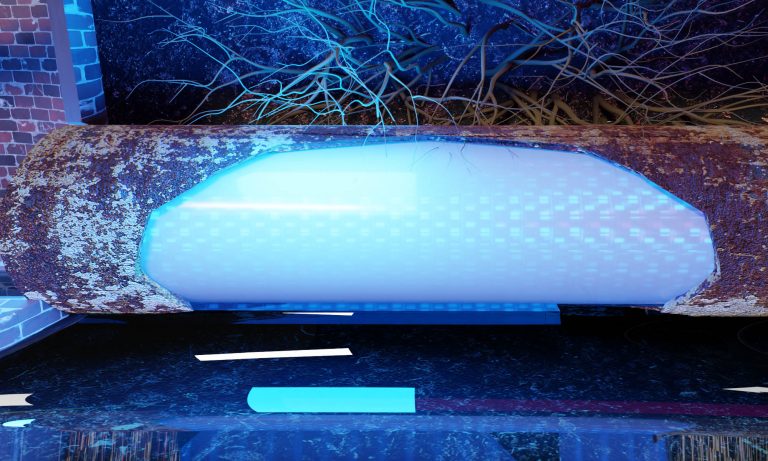

Long-Lasting Results: Trenchless pipelining employs advanced materials and techniques to create a new pipe within the existing damaged one. The resulting pipe is highly durable, resistant to corrosion, and capable of withstanding heavy usage for decades. This longevity ensures that the repaired sewer system remains functional and efficient for an extended period, saving on future repair and replacement costs.

Minimized Environmental Impact: Trenchless sewer repair helps preserve the environment by reducing the need for extensive excavation, which can disrupt ecosystems and harm surrounding vegetation. The eco-friendly nature of trenchless methods aligns with sustainable practices, making it a responsible choice for municipalities and environmentally conscious property owners.

Preserved Landscape and Aesthetics: One of the significant advantages of trenchless sewer repair is that it leaves the landscape largely intact. Property owners do not have to worry about extensive disruption to gardens, driveways, or paved areas. This method preserves the aesthetics of the property while resolving sewer pipe issues.

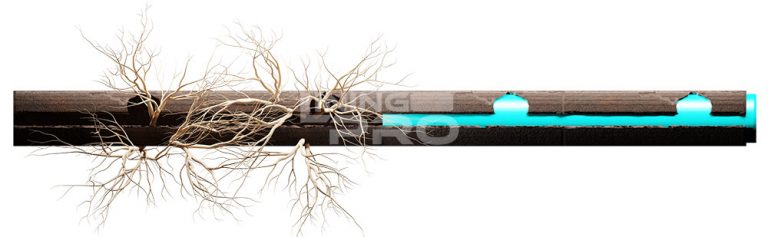

Versatility and Adaptability: Trenchless sewer repair can address a wide range of pipe problems, including cracks, leaks, root intrusions, and misaligned joints. This versatile technique can be employed in various pipe materials, such as clay, PVC, cast iron, and concrete. Its adaptability ensures that trenchless methods can effectively repair sewer pipes in different scenarios.

Reduced Health Risks: Dig-and-replace methods often expose workers and residents to health risks associated with excavation, such as exposure to hazardous gases, soil contaminants, and structural collapses. Trenchless sewer repair eliminates these risks, providing a safer working environment for technicians and ensuring the well-being of the community.

Minimal Disruption to Daily Life: Trenchless sewer repair minimizes disruptions to daily activities, as it requires less excavation and does not necessitate property evacuation during the repair process. Homeowners and businesses can continue their routines with minimal interruptions, resulting in increased satisfaction and convenience.

Superior Leak Resistance: Trenchless pipelining creates a seamless and jointless pipe within the existing damaged pipe, virtually eliminating the risk of leaks. This ensures optimal flow and prevents the infiltration of groundwater, reducing the chances of additional pipe damage and maintaining the integrity of the sewer system.

In the realm of sewer pipe repair, trenchless methods have emerged as the superior choice over traditional dig-and-replace techniques. With its enhanced efficiency, cost-effectiveness, environmental benefits, and ability to deliver long-lasting results, trenchless sewer repair is the go-to solution for property owners and municipalities alike. By opting for trenchless pipelining, you can ensure a swift, non-invasive, and reliable restoration of your sewer system, safeguarding your property, the environment, and your peace of mind.

Benefits of using trenchless in commercial structures and properties:

- Minimal disruption: Trenchless repair minimizes disruption to landscaping, driveways, sidewalks, and other structures on the property, preserving their integrity.

- Faster installation: Trenchless methods typically require less time than traditional dig and replace methods, allowing for faster completion of the repair.

- Preservation of trees and vegetation: Trenchless repair avoids damaging tree roots and allows for the preservation of landscaping and vegetation around the property.

- Longer lifespan: Trenchless pipe lining uses durable materials that can extend the lifespan of the sewer system, reducing the need for frequent replacements.

- Seamless lining: The trenchless process creates a seamless pipe within the existing damaged pipe, preventing root intrusion and future leaks.

- Increased flow capacity: Trenchless pipe lining increases the flow capacity of the sewer system by reducing friction and preventing the buildup of debris.

- Corrosion resistance: Trenchless lining materials are often corrosion-resistant, protecting the pipes from deterioration caused by chemical reactions or harsh environmental conditions.

- Improved structural integrity: The new lining reinforces the existing pipe, enhancing its structural integrity and resistance to cracks, leaks, and collapses.

- Versatility: Trenchless repair can be applied to various types of sewer pipes, including clay, cast iron, PVC, and concrete.

- Minimal risk of utility damage: Trenchless methods significantly reduce the risk of accidentally damaging underground utilities such as gas lines, water pipes, or electrical cables.

- Increased property value: Trenchless repair provides an attractive selling point, as it demonstrates that the sewer system has been updated and maintained using advanced methods.

- Limited need for excavation permits: Trenchless repair often requires fewer excavation permits or may be exempt from certain regulations, saving time and bureaucratic hassle.

- Reduction in noise and dust: Compared to traditional dig and replace methods, trenchless repair produces significantly less noise, dust, and debris, creating a more pleasant environment during the repair process.

- Minimal disruption to daily activities: Trenchless repairs allow residents and businesses to continue their daily routines with minimal interference, as there is no need to vacate the property or halt operations.

- No loss of access or parking spaces: Trenchless repairs eliminate the need for digging up streets, sidewalks, or parking lots, ensuring that access and parking spaces remain unaffected.

- Lower risk of accidents and injuries: Trenchless methods reduce the risk of accidents associated with open trenches, heavy machinery, and excavation-related hazards.

- Enhanced aesthetics: Trenchless repair maintains the visual appeal of the property since there are no unsightly trenches or construction sites left behind.

- Technological advancements: Trenchless repair benefits from ongoing technological advancements, allowing for continuous improvement and innovation in the field, ensuring more efficient and effective repairs over time.

Common Areas of Failure in Sewer Pipes: Causes and Solutions

Sewer pipes play a vital role in maintaining a clean and healthy environment by carrying wastewater away from our homes and communities. However, over time, these underground networks can face various issues that lead to failures, resulting in sewer backups, leaks, and potential health hazards. Understanding the common areas of failure in sewer pipes can help us identify the causes and implement effective solutions to prevent or address these problems promptly. Let’s explore the most frequent areas where sewer pipes commonly fail and offer insights into the underlying causes and potential remedies.

Pipe Material and Aging:

One of the primary factors contributing to sewer pipe failures is the material used in their construction. Older sewer systems predominantly consist of clay or cast iron pipes, which are prone to deterioration over time. Clay pipes can crack or collapse due to the effects of ground shifting or tree root intrusion, while cast iron pipes are susceptible to rust and corrosion.

Solution: Replacement or relining of aging sewer pipes with more durable materials such as PVC (polyvinyl chloride) or HDPE (high-density polyethylene) can significantly extend their lifespan and reduce the risk of failures.

Joint Failures:

Sewer pipes are typically composed of individual sections joined together with various types of joints, including bell and spigot, rubber gasket, or mechanical joints. These joints are vulnerable to failure due to movement, settlement, or ground shifting, leading to misaligned or separated pipe segments.

Solution: Regular inspection and maintenance, including joint sealing or resealing techniques, can help prevent joint failures. Additionally, using flexible couplings or trenchless repair methods can provide more robust connections, reducing the likelihood of joint-related issues.

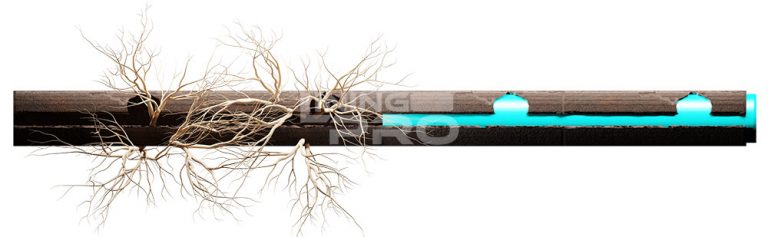

Tree Root Intrusion:

The presence of trees near sewer lines can pose a significant threat to their integrity. Tree roots are naturally attracted to the moisture and nutrients inside sewer pipes, and they can infiltrate small cracks or gaps in the pipe walls. As the roots grow, they exert pressure on the pipes, leading to cracks, blockages, and ultimately, pipe collapse.

Solution: Implementing preventative measures such as root barriers, selective tree planting, or regular root pruning can help mitigate tree root intrusion. In severe cases, pipe lining or replacement might be necessary to address extensive root damage.

Corrosion and Erosion:

Corrosion is a prevalent issue, especially in older metal pipes. The combination of the sewage’s chemical composition and the surrounding soil conditions can lead to the deterioration of the pipe walls. Similarly, erosion caused by high-velocity flows or abrasive materials can weaken the pipes, resulting in leaks or structural failures.

Solution: Treating the sewer system with anti-corrosive agents, applying protective coatings, or implementing cathodic protection systems can slow down or prevent corrosion. Proper monitoring of flow rates and implementing erosion control measures can also help minimize pipe erosion.

Hydraulic Overload and Blockages:

Sewer pipes are designed to accommodate a specific volume of wastewater flow. However, hydraulic overload can occur when the volume exceeds the pipe’s capacity, leading to excessive pressure and subsequent failures. Blockages caused by debris, grease, or foreign objects can exacerbate the issue by impeding the flow and causing backups.

Solution: Regular maintenance and cleaning of sewer lines, including jetting or snaking procedures, can prevent blockages. Implementing flow monitoring systems and hydraulic modeling can help identify areas prone to overload, enabling the necessary upgrades or adjustments to the system.

Sewer pipe failures can result in significant inconveniences, health risks, and costly repairs. Understanding the common areas where sewer pipes commonly fail allows us to address the underlying causes effectively. By implementing proactive maintenance, employing durable materials, and adopting modern repair techniques, we can ensure the longevity and reliability of our sewer systems. Regular inspections, prompt repairs, and keeping pace with technological advancements will play a crucial role in minimizing failures, ensuring the efficient and uninterrupted flow of wastewater for generations to come.

Categories

- Broken Sewer Pipes (1)

- Cast Iron Pipes (2)

- Clay Pipes (2)

- Cured In Place Pipe (CIPP) (3)

- Drain Pipe Repair (2)

- Fix Your Broken Sewer (2)

- Florida Sewer Repair (3)

- How To Fix Sewer Pipes (1)

- Jacksonville Sewer Repair (3)

- Methods of CIPP (3)

- Pull-In-Place Pipelining (1)

- Roots (1)

- Sewer Infiltration (1)

- Sewer Pipe Exfiltration (1)

- Sewer Pipe Inspections (2)

- Sewer Pipe Types (4)

- Sewer Pipes (5)

- Sewer Repair in Your Town (1)

- Tampa Sewer Repair (1)

- Top 5 Reasons (1)

- Trenchless Pipelining (5)

- Types of Sewer Damage (1)

- UV Cured In Place Pipelining (1)

Aging Cast Iron Pipes: Understanding Root Damage, Failures, and Cost-Effective Solutions

Cast iron pipes have long been used in plumbing systems due to their durability and strength. However, as these pipes age, they become susceptible to

Identifying the 20 Symptoms of a Broken Sewer Line and the Benefits of Trenchless Pipelining for Repair

A broken sewer line can wreak havoc on your property and cause significant damage if left untreated. Identifying the symptoms of a broken sewer line

Sewer Repair in Tampa, FL: Exploring Effective Solutions for a Clean and Efficient System

Maintaining a well-functioning sewer system is essential for the overall health and comfort of any community. In Tampa, Florida, where warm weather and frequent rainfall

Pull-In-Place Pipelining: A Comprehensive Guide to Installation Methods and Procedures

Pull-in-place pipelining is a highly effective and widely adopted method for rehabilitating deteriorated or damaged pipelines without the need for extensive excavation and replacement. It

Continuous Inversion Pipelining Methods: A Comprehensive Guide

In the realm of pipeline construction, continuous inversion pipelining methods have emerged as a revolutionary technique. This approach has gained traction due to its efficiency

Ultraviolet Cured In-Place Pipelining: A Revolution in Trenchless Technology

Trenchless technology has transformed the field of pipeline rehabilitation, offering efficient and cost-effective methods for repairing aging and damaged pipelines without the need for extensive

Exploring the Diverse Installation Methods of Cured-In-Place Pipelining in Sewer Systems

Maintaining the functionality and longevity of sewer systems is crucial for the smooth functioning of any city’s infrastructure. Cured-in-place pipelining (CIPP) has emerged as a

Sewer Video Inspections in Jacksonville: Exploring Common Areas for Drain Inspection and the Benefits of Trenchless Pipelining

Jacksonville, known for its vibrant culture and thriving community, is a city that is constantly growing and evolving. As the city expands, it becomes increasingly

The Pitfalls of Dig & Replace Sewer Repair: Embracing Trenchless Pipelining for Efficient and Cost-Effective Solutions

Maintaining the integrity of sewer pipes is crucial to ensure the smooth functioning of our wastewater systems. When sewer pipes develop issues, repairs become necessary

Drain Repair in Jacksonville: Trenchless Pipelining as the Preferred Method of Repair

Drainage systems are essential components of any home or office in Jacksonville. However, over time, drains can fail due to various reasons, leading to inconvenience

Revolutionizing Clay Pipe Repair: The Power of Trenchless Pipelining and Trenchless Sewer Repair

Clay pipes have long been a reliable choice for sewage and drainage systems. Their durability and longevity have served countless communities for decades. However, as

Revolutionizing Pipe Repair: Trenchless Pipelining for HDPE Pipes

When it comes to the world of infrastructure and utilities, few things are as vital as pipelines. These intricate networks ensure the efficient transportation of

Revolutionizing PVC Pipe Repair: The Power of Trenchless Pipelining

In the realm of plumbing, a broken or damaged pipe can quickly become a homeowner’s worst nightmare. Traditional repair methods, such as digging trenches to

Sewer Repair in Jacksonville, FL: Embracing Trenchless Pipelining for Efficient Solutions

Maintaining a well-functioning sewer system is crucial for the smooth operation of any city, and Jacksonville, FL, is no exception. Sewer line issues, such as

Repairing Your Sewer Line in Florida

Dealing with sewer line issues can be a major headache for homeowners and business owners alike. The thought of digging up your yard or disrupting

Top 5 Reasons Why Trenchless Pipelining is a Better Choice vs. Digging Up and Replacing Sewer Pipes

Top 5 Reasons Why Trenchless Pipelining is a Better Choice vs. Digging Up and Replacing Sewer Pipes Maintaining a functional and efficient sewer system is

Revolutionizing Household Drain Lines: The Power of Trenchless Pipelining

Imagine a world where fixing household drain lines no longer requires extensive digging, disruption, and high costs. A world where cutting-edge technology seamlessly restores the

Restoring Cast Iron Sewer Pipes: A Comprehensive Guide to Trenchless Pipelining

Introduction: Cast iron sewer pipes have long been a popular choice for residential and commercial plumbing systems due to their durability and strength. However, over

Clay Pipes: Susceptibility to Root Damage and the Cost-Effective Solution of Trenchless Pipelining

Introduction: Pipelines play a critical role in our infrastructure, providing us with essential services such as water supply and wastewater management. However, over time, various

Sewer Pipe Exfiltration: Causes, Effects, and Effective Solutions

Sewer systems play a vital role in maintaining public health and preserving the environment by safely transporting wastewater away from homes, businesses, and industrial facilities.

Understanding Sewer Pipe Infiltration and Effective Remediation Techniques

The efficient functioning of sewer systems is vital for maintaining public health and environmental sustainability. However, sewer pipe infiltration poses a significant challenge, leading to

Here’s How You Can Fix Your Sewer Pipes

When faced with sewer problems, many homeowners find themselves overwhelmed by the prospect of digging up their yards and disrupting their daily lives. Traditional sewer

The Process of Sewer Pipe Inspection

The Process of Sewer Pipe Inspection: Access Point Preparation: Before conducting a sewer pipe inspection, professionals locate the access points to the sewer system. These

The Importance of Sewer Pipe Inspection

Title: The Importance of Sewer Pipe Inspection: Saving Time and Money through Early Detection Introduction: Sewer pipe problems can cause significant headaches for property owners,

Cured-In-Place Pipelining: Revolutionizing Underground Sewer Pipe Repairs

Welcome to our comprehensive guide on cured-in-place pipelining (CIPP) and its remarkable benefits for homeowners when it comes to repairing underground sewer pipes. We will

A Comprehensive Analysis of Sewer Pipes in the United States: Types and Causes of Failure

Title: A Comprehensive Analysis of Sewer Pipes in the United States: Types and Causes of Failure Abstract: This essay delves into the diverse range of

The Destructive Power of Roots: A Menace to Sewer Pipes

The Destructive Power of Roots: A Menace to Sewer Pipes Introduction: The underground network of sewer pipes serves a vital role in ensuring the proper